Essential Insights on Boom Lift Tires

Boom lifts, also known as aerial work platforms or cherry pickers, are indispensable machines in construction, maintenance, and various industrial applications. They provide a safe and efficient way to elevate workers and equipment to great heights. While the lift’s mechanical and hydraulic systems are critical for its operation, a seemingly simple component—the boom lift tires—plays an equally vital role in ensuring safety, stability, and performance. Understanding the different types of tires and their specific uses is key to maximizing the efficiency and lifespan of your equipment.

The Two Main Types of Boom Lift Tires

When it comes to boom lift tires, you’ll primarily encounter two main categories: pneumatic and solid. Each type is designed for specific work environments and offers distinct advantages.

Pneumatic Tires are filled with air, much like those on a car or truck. They are made from a heavy-duty rubber compound and are suitable for a wide range of surfaces.

- Pros: They offer excellent shock absorption and a cushioned ride, which is ideal for rough or uneven terrain. This helps protect the machine’s components and provides a more comfortable experience for the operator. They also have a larger footprint, which helps to distribute weight more evenly and reduce ground pressure, minimizing damage to delicate surfaces like grass or paved areas.

- Cons: The primary disadvantage is the risk of punctures. A flat tire on a job site can cause significant downtime and lead to costly repairs. They also require regular pressure checks to ensure they are properly inflated for optimal performance and safety.

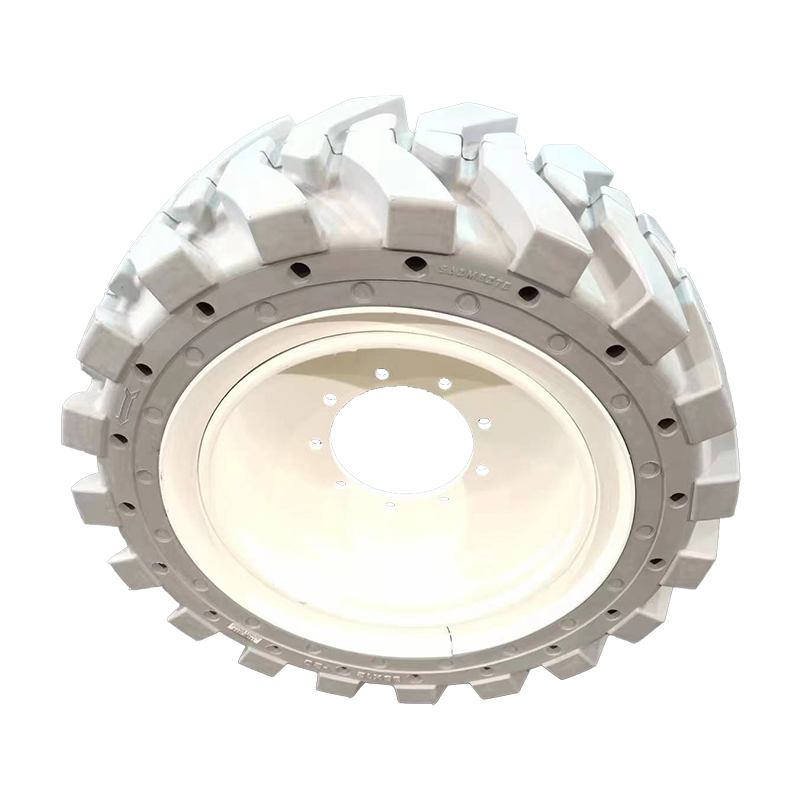

Solid Tires, also known as puncture-proof or foam-filled tires, are a robust alternative. They are made entirely of rubber or are filled with a foam compound that makes them impervious to punctures.

- Pros: Their most significant advantage is their durability and resistance to punctures. They are the ideal choice for work environments with a high risk of sharp debris, such as construction sites, scrap yards, or demolition areas. They require virtually no maintenance since they don’t need air pressure checks.

- Cons: Solid tires provide a harsher ride due to their lack of shock absorption, which can be tough on both the machine and the operator. Their hard surface can also cause damage to certain delicate indoor flooring. They are also heavier than pneumatic tires, which can slightly reduce a machine’s lifting capacity and maneuverability.

Choosing the Right Boom Lift Tires for Your Application

Selecting the correct boom lift tires depends entirely on the job site and application.

- For Outdoor Construction and Rough Terrain: If your boom lift will be primarily used outdoors on rugged ground with potential for sharp objects, solid tires are the clear winner. Their puncture resistance ensures minimal downtime and maximum productivity.

- For Landscaping or Work on Paved Surfaces: For jobs where you need to protect delicate surfaces, such as manicured lawns, sidewalks, or indoor warehouse floors, pneumatic tires are a better choice. The larger footprint and cushioned ride will prevent damage and provide a smoother operation.

- For Versatility: Some manufacturers offer foam-filled pneumatic tires, which combine the benefits of both types. They provide a softer ride than a solid tire while being completely puncture-proof, offering a great middle-ground solution for versatile work environments.

Regardless of the type, remember that proper maintenance, including regular inspections for wear and tear, is crucial for the safety and longevity of your boom lift tires and, by extension, your entire machine. A well-maintained tire is a safe tire.

CONTACT US

-

Email: SMT001@saimeite-tyre.com

-

Phone: +86-18451337018No. 1, Renmin South Road, Yandu District, Yancheng City, Jiangsu Province, China

English

English 한국어

한국어 Français

Français Español

Español