The Ultimate Guide to Selecting and Maintaining Scissor Lift Tires

Understanding Common Scissor Lift Tire Types

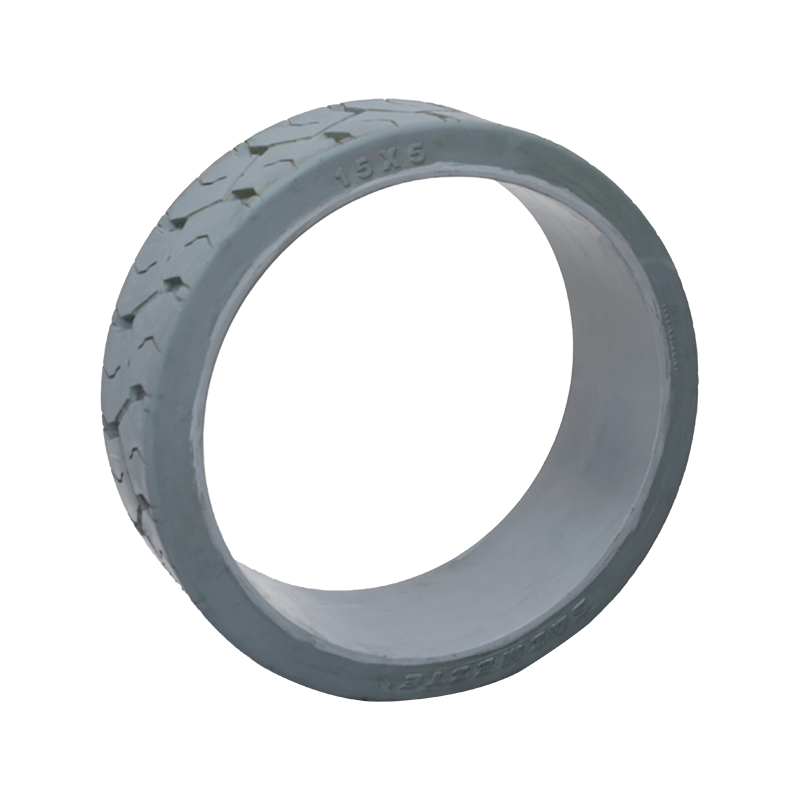

Selecting the right tire for a scissor lift is not just about fitment; it is about the environment in which the machine operates. Most indoor scissor lifts utilize non-marking solid rubber tires. These are engineered to prevent black streaks on finished flooring like epoxy or polished concrete. For outdoor or rough terrain models, you will typically find foam-filled pneumatic tires. These provide the traction and shock absorption of air-filled tires but are immune to punctures from nails, gravel, or rebar found on construction sites.

While less common, some specialized lifts use poly-filled tires. These offer a middle ground, providing a smoother ride than solid rubber while maintaining a high load-bearing capacity. Understanding these distinctions ensures that you don't accidentally damage a client's floor or end up with a flat tire in the middle of a high-stakes outdoor project.

Key Specifications and Comparisons

When replacing tires, it is vital to match the load capacity and the hardness (durometer) of the rubber to the manufacturer’s original specifications. A tire that is too soft may degrade quickly under heavy loads, while a tire that is too hard may lack the necessary grip for safe operation on inclined surfaces.

| Tire Feature | Solid Non-Marking | Foam-Filled Pneumatic |

| Primary Surface | Indoor/Smooth Concrete | Outdoor/Rough Terrain |

| Durability | High (Wear Resistant) | High (Puncture Proof) |

| Floor Protection | Excellent (No Streaks) | Low (Heavy Tread) |

Critical Maintenance and Safety Inspections

Because scissor lifts operate at significant heights, tire integrity is a primary safety concern. Even a small chunk missing from a tire can cause the machine to lean dangerously when the platform is fully extended. Operators should perform a visual "walk-around" inspection before every shift to identify potential hazards before they lead to an accident.

What to Look for During Inspection

- Significant "chunking" or deep gouges in the sidewalls or tread area.

- Flat spots caused by skidding or leaving the machine stationary for too long under heavy loads.

- Evidence of "delamination," where the rubber begins to peel away from the metal rim.

- Loose or missing lug nuts, which can lead to wheel wobble or complete detachment.

When to Replace Your Scissor Lift Tires

Determining the exact moment for replacement helps balance cost-efficiency with safety. Most manufacturers provide a "wear line" on the sidewall of the tire. Once the tread has worn down to this line, the tire no longer provides the necessary stability or traction and must be replaced. Continuing to operate past this point increases the risk of the lift tipping or slipping.

Additionally, if you notice the machine vibrating excessively during travel, it is often a sign of uneven wear or internal tire failure. Replacing tires in pairs (both front or both rear) is highly recommended. This ensures that the axle remains level, which is crucial for the computerized tilt-sensors found on modern aerial work platforms to function correctly.

CONTACT US

-

Email: SMT001@saimeite-tyre.com

-

Phone: +86-18451337018No. 1, Renmin South Road, Yandu District, Yancheng City, Jiangsu Province, China

English

English 한국어

한국어 Français

Français Español

Español